Фабричка по меру обрада алуминијума, прецизни делови полупроводничких компонената, сервиси за CNC обраду делова

- Преглед

- Препоручени производи

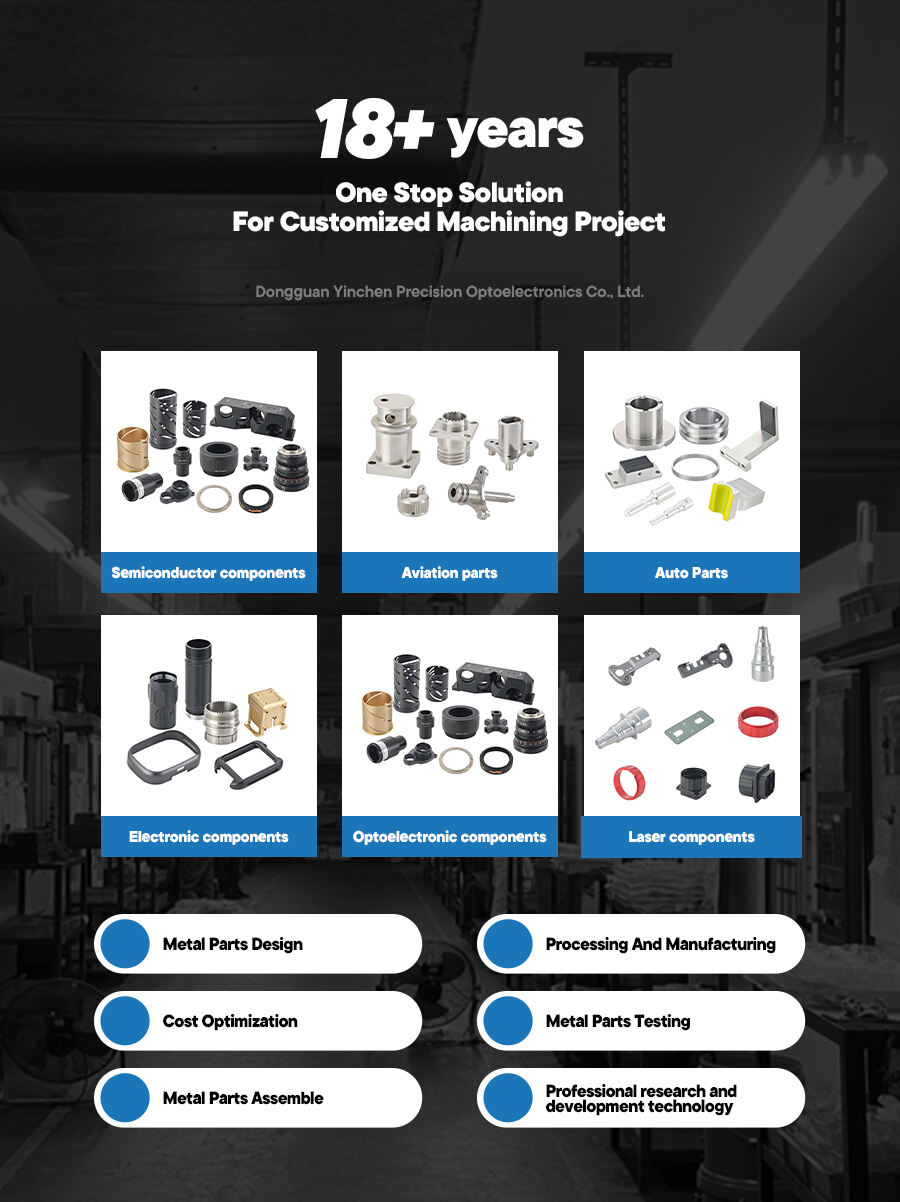

Predstavljamo, Yinchen Factory Custom Machining Aluminijumske Precizne Poluprovodničke Komponente Delove Uslove CNC Mašiniranja!

Da li imate potrebu za visokokvalitetnim, precizno obrađenim komponentama za vašu poluprovodničku opremu? Ne tražite nigde drugde do Yinchen CNC usluga mašiniranja. Naš stručni tim mašinista specijalizovan je za izradu pojedinačnih delova koji zadovoljavaju vaše tačne specifikacije.

Koristeći opremu najnovije generacije i napredne tehnologije, u stanju smo da proizvodimo aluminijumske komponente izuzetne preciznosti i tačnosti. Bez obzira da li vam trebaju složeni delovi sa kompleksnim geometrijama ili jednostavni delovi sa uskim tolerancijama, naš tim može da isporuči idealno rešenje za vaše poluprovodničke primene.

У Yinchen-у разумемо важност квалитета и поузданости у индустрији полупроводника. Зато користимо само највише квалитетне материјале и придржавамо се строгих стандарда контроле квалитета током целокупног процеса производње. Можете бити сигурни да ће ваше компоненте испунити или премашити ваша очекивања сваки пут.

Наша CNC обрада је идеална за широк спектар примене у индустрији полупроводника, укључујући РФ појачала, појачала снаге, филтере и још много тога. Без обзира на комплексност вашег дизајна, наш тим поседује експертизу и искуство да би вашу визију претворио у стварност.

Поред наших прецизних капацитета обраде, такође нудимо брзо време испоруке и конкурентне цене. Разумемо потребу за брзим циклусима производње у индустрији полупроводника и посветили смо се да ваше прилагођене компоненте испоручимо на време и у оквиру предвиђеног буџета.

Kada odaberete delove za CNC obradu aluminijumskih preciznih poluprovodničkih komponenti, prilagođene proizvodnji u fabrici Yinchen, možete biti sigurni da dobijate najviši kvalitet, preciznost i pouzdanost. Kontaktirajte nas danas da saznate više o tome kako vam možemo pomoći u zadovoljenju vaših potreba za poluprovodničkim komponentama

Наше услуге |

CNC обрада ротацијом, CNC фрезирање, ливење под притиском, електроерозија (EDM), ливење у калупе |

|||||||

Доступни материјали

|

Алуминијум: серија 2000, серија 6000, 7075, 5052, итд. |

|||||||

Нерђајући челик: SUS303, SUS304, SS316, SS316L, 17-4PH итд. |

||||||||

Челик: 1214Л/1215/1045/4140/СЦМ440/40ЦрМо, итд. |

||||||||

Мед: 260, C360, H59, H60, H62, H63, H65, H68, H70, Бронз, Бакар |

||||||||

Титан: Степен F1-F5 |

||||||||

Пластика: Ацетал/ПОМ/ПА/Нилон/ПЦ/ПММА/ПВЦ/ПУ/Акрил/АБС/ПТФЕ/ПЕЕК итд. |

||||||||

Површинска обрада

|

Анодизација, Тестерисање, Штампање у седење, PVD покривање, Цинка/Никел/Хром/Титанијум покривање, Четкање, Боење, Прашинаста заштита, Пасивирање, Електрофореза, Полирање струјом, Гребен, Ласер/Трављење/Гравирање итд |

|||||||

Толеранција |

±0,002 ~ ±0,005 mm ili prilagođeno |

|||||||

Огробност површине |

Min Ra 0,1~3,2 ili prilagođeno |

|||||||

П: ДА ЛИ СТЕ ВИ ФАБРИКА ИЛИ ТРГОВИНСКА КОМПАНИЈА

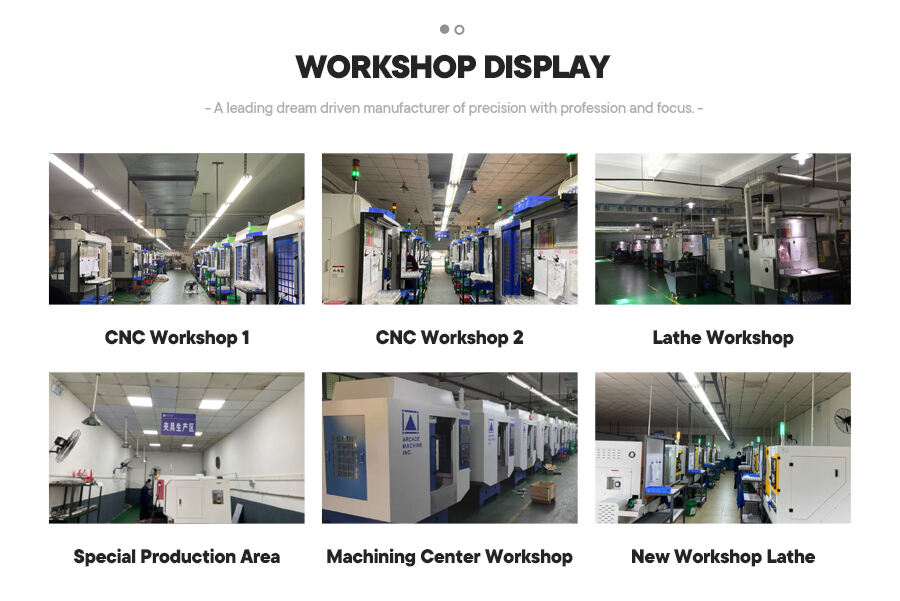

О: Ми смо фабрика која се налази у Донггуан Кина. Добродошли да посетите нашу фабрику

П: КОЛИКО НАМА ТРАЈЕ ПОНУДА

О: Након добијања детаљних информација (ваши 2D/3D цртежи или узорци), ми ћемо вам понудити у року од 2 дана

П: КАКО МОЖЕТЕ ОСИГУРАТИ КВАЛИТЕТ

A: Imamo odeljenje za kontrolu kvaliteta koje prati kvalitet od početka proizvodnje do završetka gotovih proizvoda. Imamo kompletan set inspekcione opreme, a izveštaj o kontroli kvaliteta biće poslat zajedno sa svakom partijom robe

P: ŽELIM DA OČUVAM DIZAJN U TAJNOSTI, MOŽEMO LI POTPISATI SPORAZUM O POVJERNOM ODNOSU

A: Da, možemo potpisati sporazum o povjerenoj saradnji, nećemo otkrivati dizajne naših klijenata niti ih pokazivati drugima

P: KAKAV FORMAT CRTAĆA VAM JE POTREBAN ZA PROIZVODNJU

A: 2D i 3D formati su dostupni. 2D kao PDF, CAD, JPG itd. 3D kao STEP, STP, IGS, STL itd

P: MOŽETE LI SE STROGO PRIDRŽAVATI TOLERANCIJA NA CRTAĆU I OBEZBEDITI VISOKU TAČNOST

O: Da, možemo. Možemo isporučiti delove visoke tačnosti i napraviti ih prema vašem crtežu.