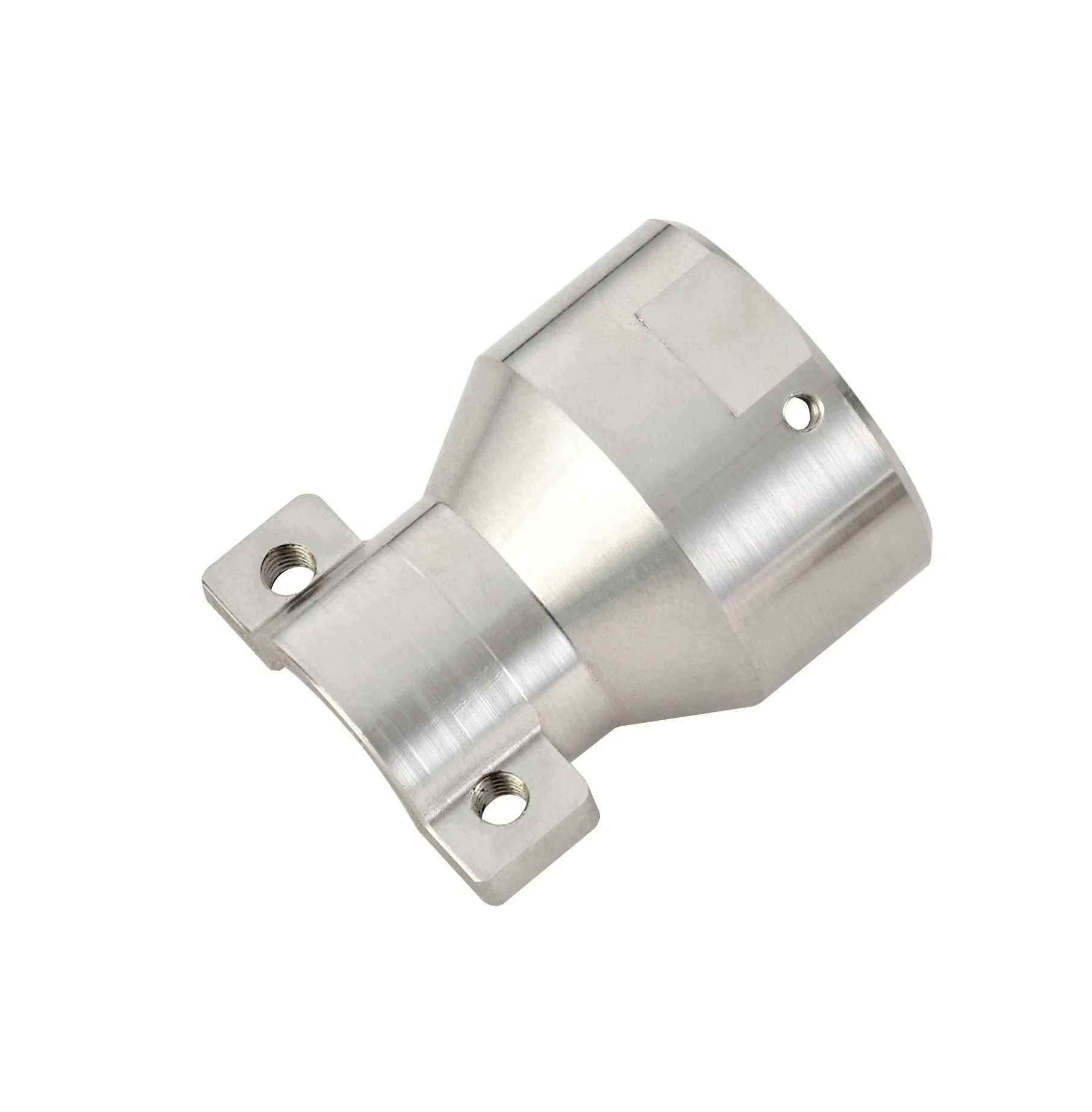

Five-axis Linkage Non-Standard Stainless Steel Anodized Aluminum Alloy Structural Parts for Semiconductor Component Processing

- Overview

- Recommended Products

Yinchen

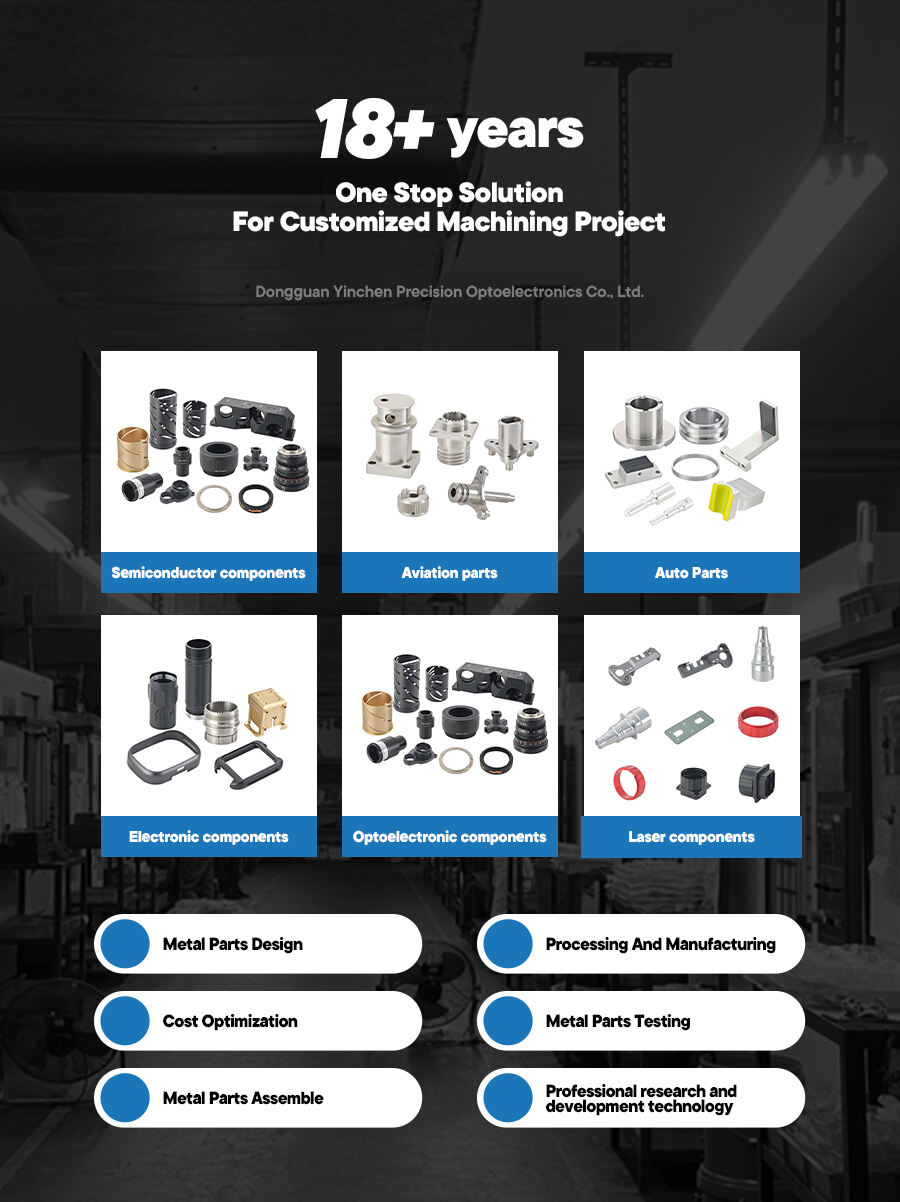

Introducing the Yinchen Five-axis Linkage Non-Standard Stainless Steel Anodized Aluminum Alloy Structural Parts for Semiconductor Component Processing. This innovative product is designed for precision and efficiency in the manufacturing of semiconductor components.

The structural parts are made from high-quality stainless steel and anodized aluminum alloy, ensuring durability and resistance to corrosion. The Yinchen five-axis linkage technology allows for multi-angle machining, resulting in highly accurate and complex shapes that meet the stringent requirements of semiconductor processing.

With Yinchen's meticulous craftsmanship and attention to detail, these structural parts are carefully engineered to provide seamless integration with semiconductor processing equipment. The non-standard design allows for customization and versatility in meeting specific requirements for different semiconductor components.

Whether you are in need of components for microchips, sensors, or circuits, the Yinchen Five-axis Linkage Structural Parts are the perfect solution. Their precision and reliability make them an essential tool for semiconductor manufacturers looking to produce high-quality components with efficiency and consistency.

In addition to their functional benefits, these structural parts are also aesthetically pleasing with a sleek anodized finish that enhances their appearance. The combination of stainless steel and aluminum alloy not only provides superior strength and durability but also gives them a modern and sophisticated look.

Experience the difference that Yinchen Five-axis Linkage Non-Standard Stainless Steel Anodized Aluminum Alloy Structural Parts can make in your semiconductor component processing. With their superior quality, precision engineering, and customizable design, these parts are sure to enhance the efficiency and performance of your manufacturing processes.

Choose Yinchen for your semiconductor processing needs and take your production to the next level with the unmatched quality and reliability of our Five-axis Linkage Structural Parts. Trust in Yinchen to deliver exceptional products that will meet and exceed your expectations.

Our Services |

CNC Turning, CNC Milling, Die Casting, Electric Discharge Machining (EDM), Injection Molding. |

|||||||

Materials Available

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

|||||||

Stainless Steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper. |

||||||||

Titanium: Grade F1-F5. |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

||||||||

Surface Treatment

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

|||||||

Tolerance |

±0.002 ~ ±0.005mm or custom |

|||||||

Surface Roughness |

Min Ra 0.1~3.2 or custom |

|||||||

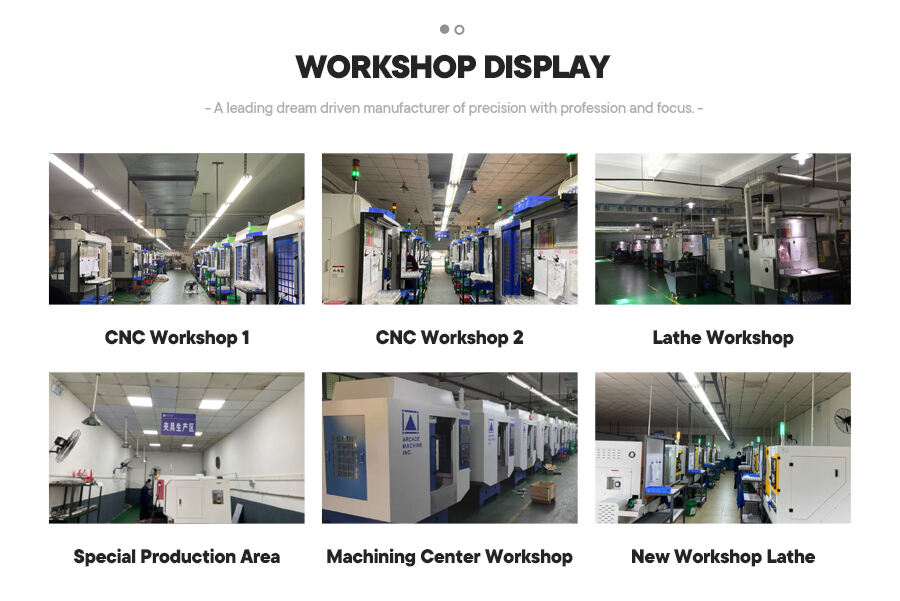

Q: ARE YOUR FACTORY OR TRADE COMPANY? A: We are a factory located in Dongguan China. Welcome to visit our factory.

Q: HOW LONG SHOULD WE TAKE FOR A QUOTATION?

A: After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

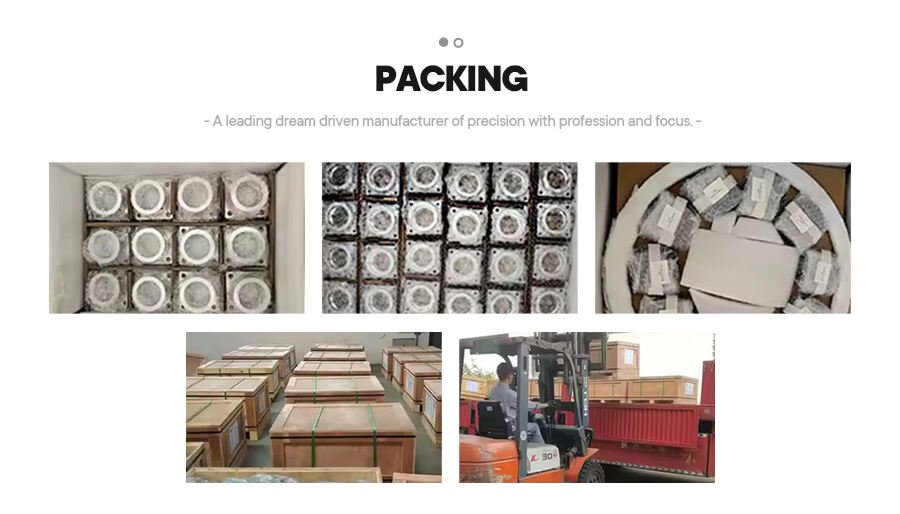

Q: HOW CAN YOU ENSURE THE QUALITY? A: We have QC department to control the quality from the beginning of production until goods finish. We have full set of inspection equipment, quality inspection report will be sent together with each batch goods.

Q: I WANT TO KEEP OUR DESIGN IN SECRET, CAN WE SIGN NDA? A: Yes, we can sign NDA, we will not disclose any customers' design or show to other people.

Q: WHAT DRAWINGS FORMAT YOU NEED FOR PRODUCTION? A: 2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STEP, STP, IGS, STL etc.

Q: CAN YOU STRICTLY FOLLOW THE TOLERANCE ON THE DRAWING AND MEETTHE HIGH PRECISION? A: Yes, we can, we can provide high precision parts and make the parts as your drawing.