Factory Direct Custom Precision Photoelectric Component Parts 5-Axis CNC Machining Services for Industrial Equipment Stainless

- Overview

- Recommended Products

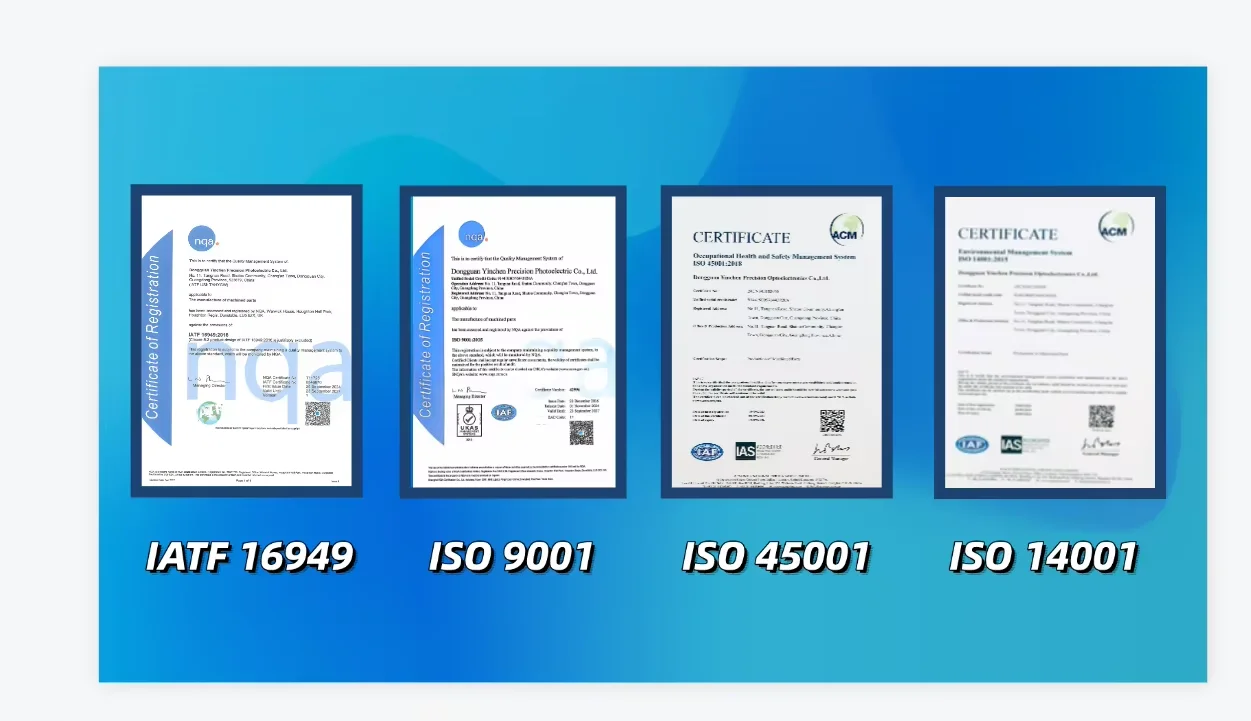

Introducing, Yinchen’s Factory Direct Custom Precision Photoelectric Component Parts 5-Axis CNC Machining Services for Industrial Equipment Stainless.

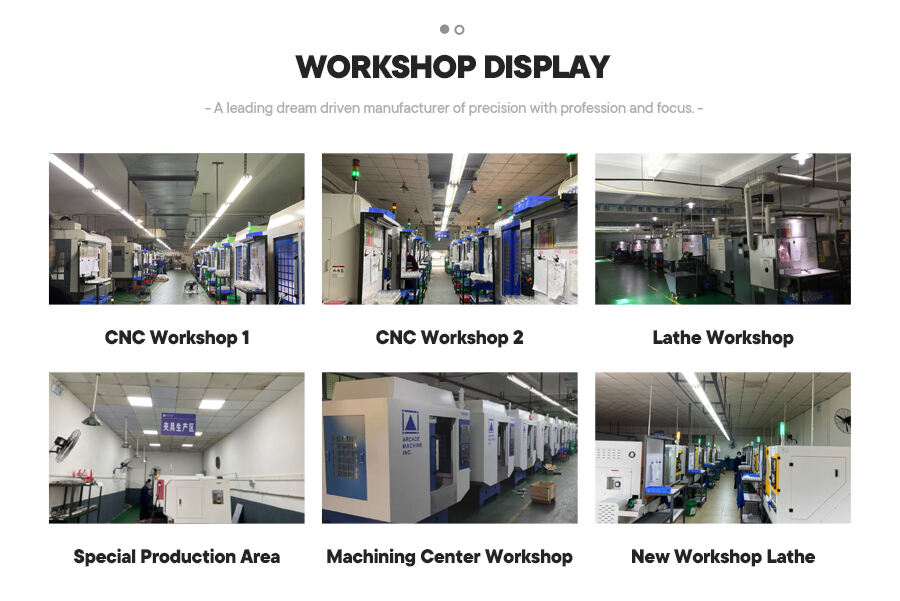

Yinchen offers top-of-the-line CNC machining services for industrial equipment, specializing in precision photoelectric component parts. Our state-of-the-art 5-axis CNC machines deliver unparalleled accuracy and consistency, ensuring that each part meets the highest industry standards.

With Yinchen's factory direct services, you can expect quick turnaround times and competitive pricing without sacrificing quality. Our team of skilled technicians and engineers work closely with you to understand your specific needs and specifications, guaranteeing that each part is tailored to your exact requirements.

Whether you need custom photoelectric sensors, connectors, or other precision components, Yinchen has the expertise and capabilities to deliver the perfect solution for your industrial equipment. Our precision machining services ensure that each part is manufactured to precise tolerances, ensuring optimal performance and reliability in your equipment.

At Yinchen, we are committed to providing the highest quality products and services to our customers. Our dedication to excellence is reflected in every part we produce, ensuring that you receive the best possible solution for your industrial equipment needs.

Experience the difference of Yinchen's Factory Direct Custom Precision Photoelectric Component Parts 5-Axis CNC Machining Services for Industrial Equipment Stainless. Trust in our expertise and craftsmanship to deliver the perfect solution for your precision component needs. Contact us today to learn more about how we can help you achieve your manufacturing goals

Our Services |

CNC Turning, CNC Milling, Die Casting, Electric Discharge Machining (EDM), Injection Molding |

|||||||

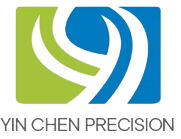

Materials Available

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|||||||

Stainless Steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

||||||||

Titanium: Grade F1-F5 |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

||||||||

Surface Treatment

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|||||||

Tolerance |

±0.002 ~ ±0.005mm or custom |

|||||||

Surface Roughness |

Min Ra 0.1~3.2 or custom |

|||||||

Q : ARE YOUR FACTORY OR TRADE COMPANY

A : We are a factory located in Dongguan China. Welcome to visit our factory

Q : HOW LONG SHOULD WE TAKE FOR A QUOTATION

A : After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

Q : HOW CAN YOU ENSURE THE QUALITY

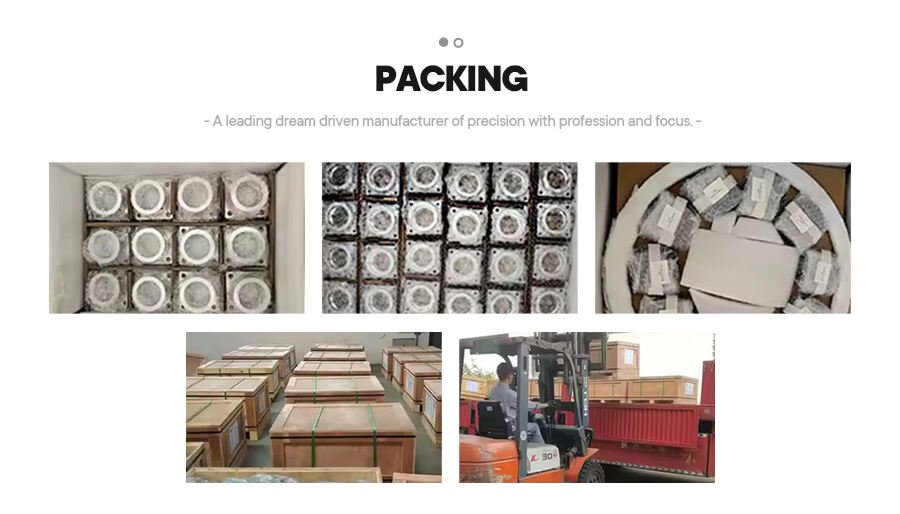

A : We have QC department to control the quality from the beginning of production until goods finish. We have full set of inspection equipment, quality inspection report will be sent together with each batch goods

Q : I WANT TO KEEP OUR DESIGN IN SECRET, CAN WE SIGN NDA

A: Yes, we can sign NDA, we will not disclose any customers' design or show to other people

Q : WHAT DRAWINGS FORMAT YOU NEED FOR PRODUCTION

A: 2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STEP, STP, IGS, STL etc

Q : CAN YOU STRICTLY FOLLOW THE TOLERANCE ON THE DRAWING AND MEETTHE HIGH PRECISION

A : Yes, we can, we can provide high precision parts and make the parts as your drawing.