Best Professional Custom CNC Aluminum & Stainless Steel Machining Turning Processing Services for Semiconductor Component Parts

- Overview

- Recommended Products

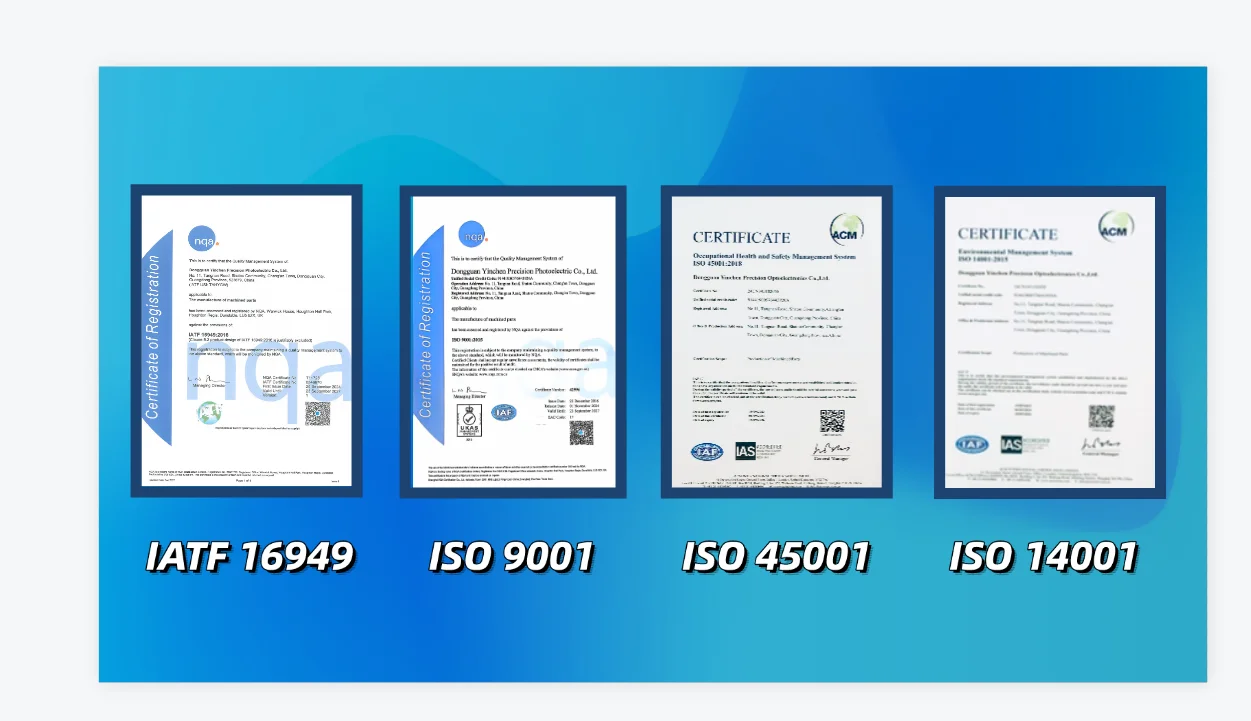

Introducing, Yinchen's top-of-the-line professional custom CNC aluminum and stainless steel machining turning processing services for semiconductor component parts. Whether you are in need of precision parts for your semiconductor industry applications, Yinchen has you covered with their expert machining services.

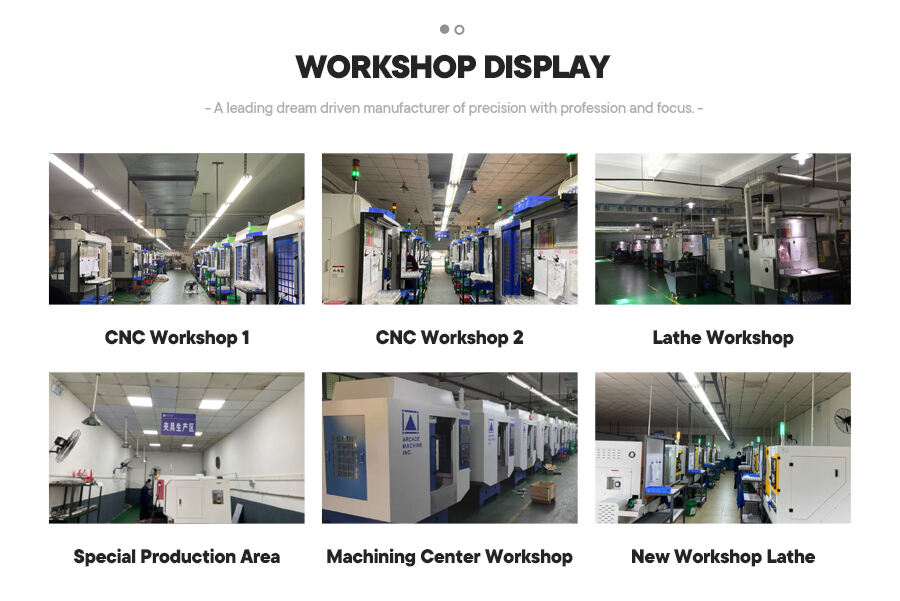

Yinchen's advanced CNC technology ensures that every component produced is of the highest quality and accuracy. Their team of skilled technicians is experienced in working with a wide range of materials, including aluminum and stainless steel, to meet the specific needs of the semiconductor industry.

With Yinchen's custom machining services, you can expect fast turnaround times and competitive pricing without sacrificing quality. Their state-of-the-art equipment allows for intricate and complex parts to be fabricated with precision and efficiency.

Yinchen's commitment to customer satisfaction is evident in the impeccable finish and accuracy of each component produced. Their attention to detail and dedication to delivering superior products sets them apart as a leader in the industry.

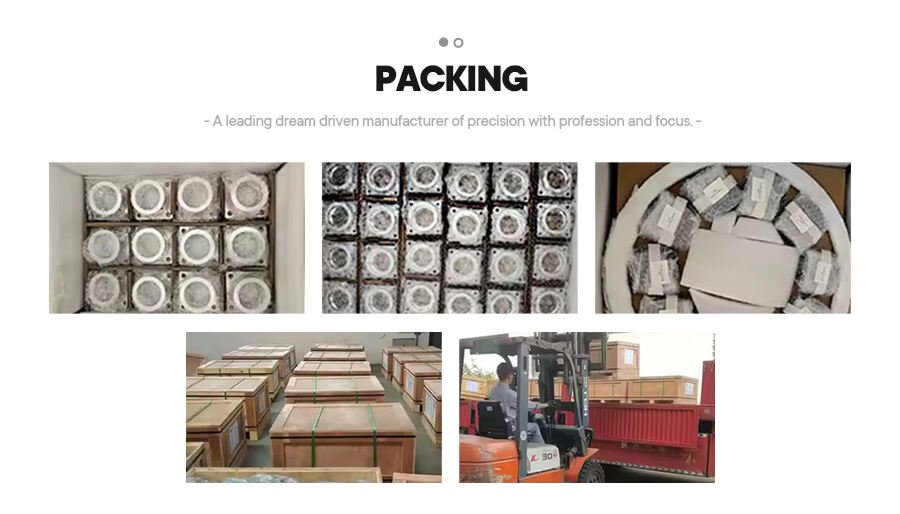

Whether you require small batches or large volume production runs, Yinchen can accommodate your needs with their flexible machining capabilities. Their expert team is equipped to handle projects of any size and complexity, delivering consistent results that exceed expectations.

Yinchen's custom CNC aluminum and stainless steel machining turning processing services are ideal for semiconductor component parts that require precise tolerances and high quality finishes. Whether you need components for semiconductor manufacturing equipment or electronic devices, Yinchen has the expertise to deliver superior results.

Trust Yinchen for all your semiconductor component part machining needs. With their unmatched precision, quality, and dedication to customer satisfaction, Yinchen is the trusted choice for professional CNC aluminum and stainless steel machining turning processing services. Contact Yinchen today to discuss how they can help meet your specific machining needs and elevate the performance of your semiconductor components

Our Services |

CNC Turning, CNC Milling, Die Casting, Electric Discharge Machining (EDM), Injection Molding |

|||||||

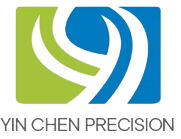

Materials Available

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|||||||

Stainless Steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

||||||||

Titanium: Grade F1-F5 |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

||||||||

Surface Treatment

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|||||||

Tolerance |

±0.002 ~ ±0.005mm or custom |

|||||||

Surface Roughness |

Min Ra 0.1~3.2 or custom |

|||||||

Q : ARE YOUR FACTORY OR TRADE COMPANY

A : We are a factory located in Dongguan China. Welcome to visit our factory

Q : HOW LONG SHOULD WE TAKE FOR A QUOTATION

A : After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

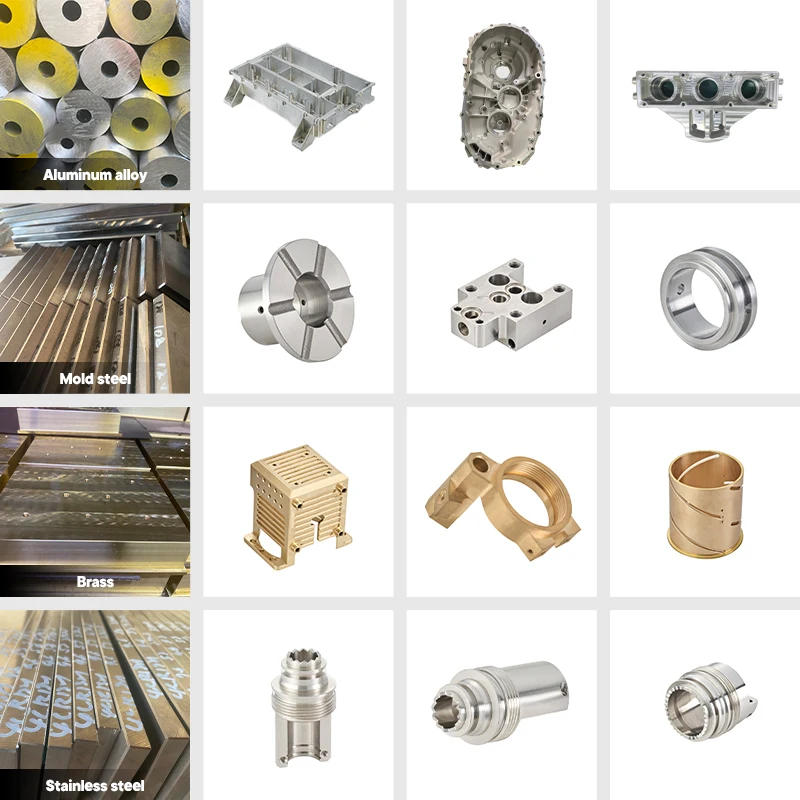

Q : HOW CAN YOU ENSURE THE QUALITY

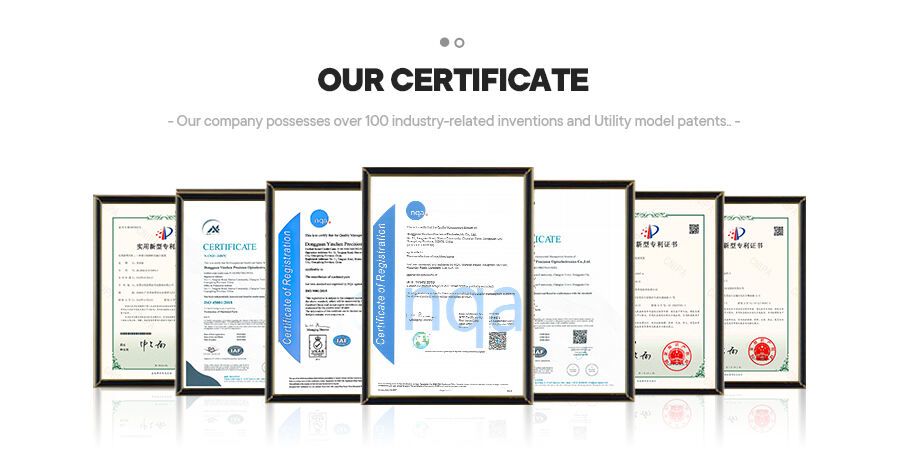

A : We have QC department to control the quality from the beginning of production until goods finish. We have full set of inspection equipment, quality inspection report will be sent together with each batch goods

Q : I WANT TO KEEP OUR DESIGN IN SECRET, CAN WE SIGN NDA

A: Yes, we can sign NDA, we will not disclose any customers' design or show to other people

Q : WHAT DRAWINGS FORMAT YOU NEED FOR PRODUCTION

A: 2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STEP, STP, IGS, STL etc

Q : CAN YOU STRICTLY FOLLOW THE TOLERANCE ON THE DRAWING AND MEETTHE HIGH PRECISION

A : Yes, we can, we can provide high precision parts and make the parts as your drawing.