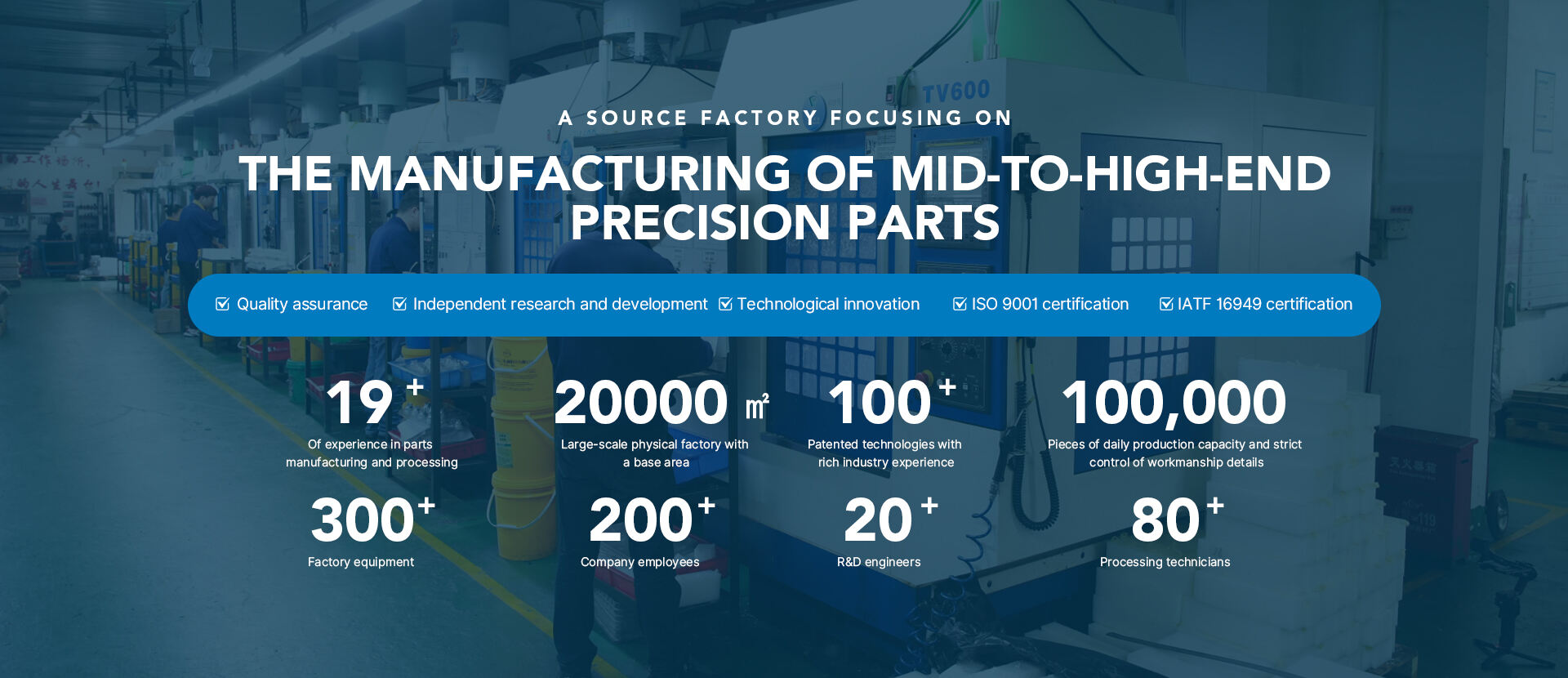

Our Manufacturing Capabilities

Yinchen provides a range of manufacturing capabilities to support rapid prototyping and both low and high-volume production needs. With our own factory and a reliable Chinese network, we deliver complex, high-quality parts efficiently.

The optical metal structural component

The optical metal structural component 7075 is processed by CNC.

The diameter tolerance of the circular hole is within ±0.01mm, the shape is ±0.05mm, the positional accuracy is 0.03mm, and the surface roughness is Ra0.8 - Ra1.6μm, ensuring the optical performance.

New energy structural components

New energy structural components, made of aluminum alloy 6061, processed by CNC milling and drilling.

The aperture tolerance is within 0.02mm, the flatness is 0.02mm, and it undergoes anodic oxidation treatment to ensure assembly and corrosion resistance.

Precision parts for semiconductor equipment

The material is 2A12. The diameter tolerance of the circular hole is 0.01mm and the positional tolerance is 0.02mm.

The outer diameter tolerance of the toothed cylindrical cylinder is 0.015mm, and the pitch tolerance is ±0.01mm, ensuring the high-precision requirements for assembly and adjustment.

Aerospace parts

Aerospace parts, made of aluminum alloy 6061, treated with anodic oxidation.

Processed by CNC, the positional tolerance of the installation hole is 0.03mm, and the dimensional tolerance of the cavity is ±0.05mm, meeting the assembly requirements.

Camera lens assembly

Aviation-grade aluminum alloy for the main body, titanium alloy for key parts, focusing accuracy 0.01mm.

Industrial instrument components: Commonly used are stainless steel and Yin steel, with a linear positioning accuracy of 0.005mm.

The inner diameter accuracy

The inner diameter accuracy of the cylinder block and cylinder barrel of the automotive engine is 0.03mm, and the cylindricity is 0.002-0.005mm.

The heat dissipation can reduce the temperature of the cylinder block by 10-15℃.

Automation equipment connection parts

The material is usually stainless steel.

The coaxiality of the positioning holes can reach 0.02mm, the flatness can reach 0.03mm, and the position accuracy of the bolt holes is ±0.05mm, ensuring the assembly accuracy of the equipment and improving the operational stability.

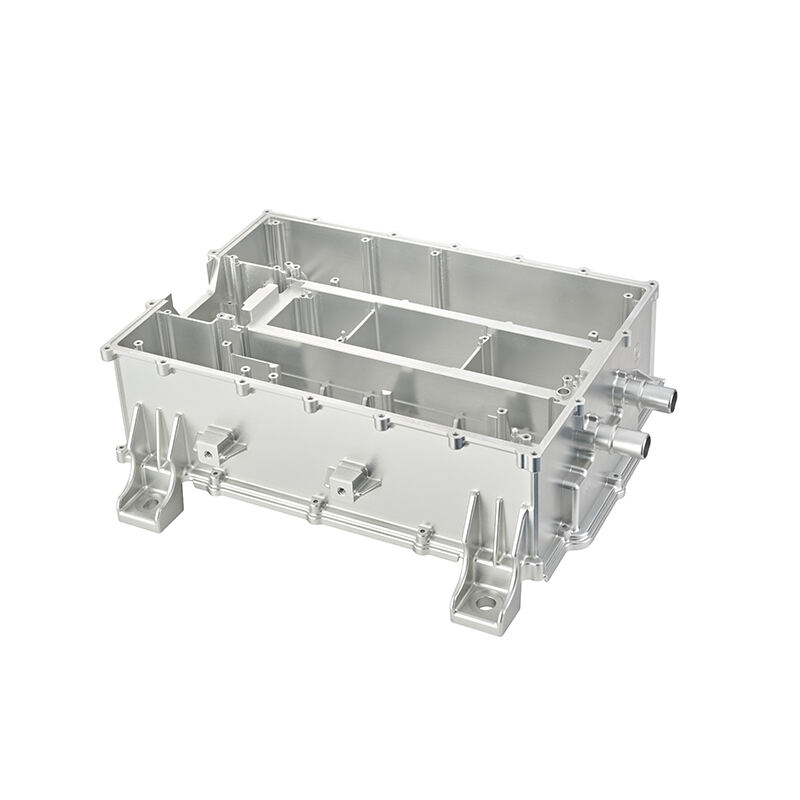

The battery box of new energy vehicles

The battery box of new energy vehicles is mostly made of aluminum alloy, reducing weight by 40-50%.

It has an IP rating of IP67 and a dimensional accuracy of ±0.02mm, ensuring battery safety and installation.